CDA-technology

CDA stands for Controlled Droplet Application.

CDA stands for Controlled Droplet Application.

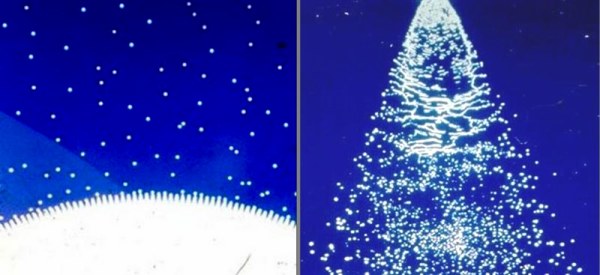

A rotating nozzle disc enables the targeted application of fine droplets with a defined spectrum at low spray quantities.

Evenly large droplets are formed at its serrated edge and centrifuged outwards, where they then sink downwards under gravity.

CDA spray pattern result on water-sensitive paper

CDA Spray Nozzle Comparison of CDA to conventional spray nozzle

Instead of the usual 300 - 600 litres of broth per hectare, approx.

10 - 30 litres per hectare are sufficient for the same amount of

herbicide; the preparation is therefore applied in a more concentrated

manner.

Many years of practical experience are available with

glyphosate products (e.g. Roundup® UltraMax and Basta®). Depending on

the type of device, the drop size is approx. 200 - 300µ. The result:

optimum distribution with minimum risk of drift.

Advantages of CDA devices

Operational efficiency:

- Cost savings due to reduced spray agent and water saving

- Droplet distribution and uniform droplet size for better spray results

- Significantly faster spraying process

Increased productivity:

- Significantly less spray liquid required compared to conventional nozzle technology

- Time expenditure considerably reduced

- CDA handheld devices greatly reduce physical exertion compared to conventional backpack sprayers

Safe spraying:

- Reduces operating errors due to fatigue, as the process is less strenuous than with a backpack sprayer

- Fewer mixing and filling operations where contamination is most likely

Lower environmental impact:

- Reduced water consumption

- Lower contamination of the soil in comparison to spraying with a nozzle, as well as considerably more targeted spreading